PRODUCTS

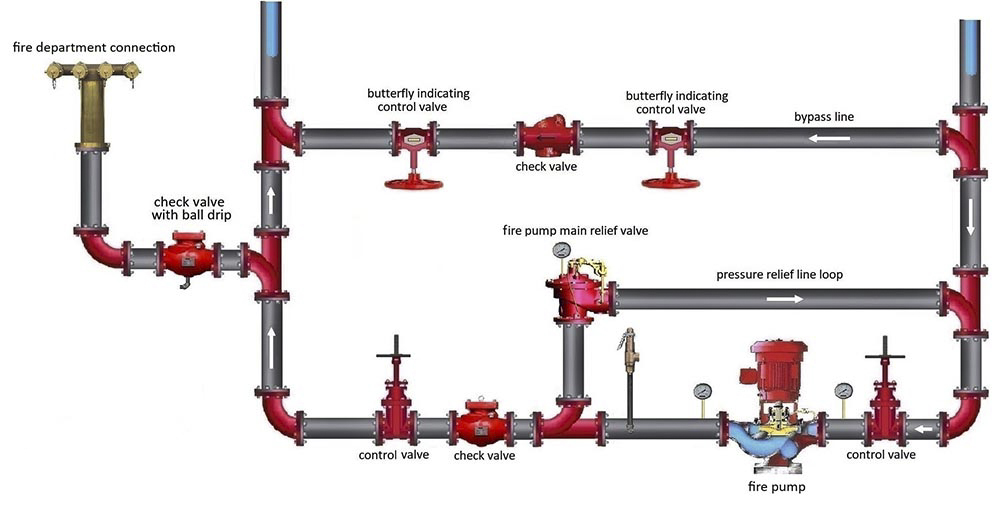

Fire pump systems are used to meet the critical water flow and pressure calculated as a result of the design of extinguishing systems.

They continuously supply water at the necessary flow and pressure to all systems that require pressurized water, such as sprinklers, fire cabinets, and indoor and outdoor hydrant systems.

What are the Main Features that Differentiate Fire Pumps from Other Booster Groups?

Unlike water boosters, fire pumps have horizontal parallel operating curves (flow-pressure optimization).

Fire pump systems consist of main pumps and jockey pumps. The main pumps are always provided with redundancy.

Precautions are taken against power outages to ensure that fire pumps operate even in the worst-case scenarios.

Periodic testing and maintenance of fire pumps are mandatory.

What are the Pump Selection Criteria According to the Turkish Fire Protection Regulation and NFPA20?

The three main factors to pay attention to regarding fire pumps are:

• The pressure value obtained when the pump reaches 150% of its nominal flow rate should not be less than 65% of the nominal pressure value.

• The pressure value obtained against a closed valve (at 0% flow) should not exceed 140% of the nominal pressure.

• The declared flow and pressure values must be verified to meet the reference values (kW / hP) and to be manufactured for the intended use.

• According to Suction Type and Physical Characteristics

• End Suction Fire Pumps

• Horizontal Split-Case Fire Pumps

• Vertical Turbine Fire Pumps

• Electric Motor-Driven Fire Pumps

• Diesel Engine-Driven Fire Pumps

• The most preferred design standards for these systems worldwide are NFPA20 and EN12845.

• Designs should be made according to the same standard covering the entire system and equipment, and product types should be selected accordingly.

• It is very important that the systems are tested and approved by internationally accredited organizations such as UL, FM, and VdS.

• Fire pump systems have many auxiliary peripheral equipment such as relief valves, waste cones, flow meters, manometers, vacuum meters, and test valves.

• The types and characteristics of these peripheral equipment are determined according to the flow and pressure values of the main pumps (primary and backup).

X

We use legal cookies to provide you with a better service. For information COOKIE POLICY ve PRIVACY POLICY Check out our sections.